How it all started

It all started in 1984 in Germany, when the founders of hpg Plastics partnered with DOW Chemicals to develop a modern resin with improved properties compared to the industry-standard at the time. Together they developed the very first PE-RT resin that would revolutionize the sanitary and heating market forever due to its advanced characteristics.

1982

Company Formation

1984

hpg Plastics develops the first PE-RT resin in cooperation with DOW Chemicals

1985

Production of the first PE-RT pipe on the market worldwide at hpg Plastics

2004

Development and market entry of the first 5-layer PE-RT pipe

2005

hpg Plastics receives the first CE conformity marking in the world for its underfloor heating systems with PE-RT resins

2006

Development and market entry of hpg FLEXOLEN®, probably the most flexible pipe on the market

2011

Development of the >me8nder< dry installation system for renovation applications

2015

Market entry of the hpg <MIDI>inverse®, an innovative PE-RT pipe with an inverted layer structure

2023

Acquisition of hpg Plastics GmbH by the Huliot Group

1982

Unternehmensgründung

1984

Entwicklung des ersten PE-RT-Kunststoffes in Kooperation zwischen DOW Chemicals und hpg Plastics

1985

Produktion des ersten PE-RT-Rohres der Welt bei hpg Plastics

2004

Entwicklung und Markteinführung des ersten fünfschichtigen PE-RT-Rohrs

2005

hpg plastics erhält die weltweit erste CE-Kennzeichnung für seine Fußboden-Heizungssysteme mit PE-RT-Kunststoffen

2006

Entwicklung und Markteinführung von hpg FLEXOLEN® >MIDI<Soft, dem wohl flexibelsten Rohr auf dem Markt

2011

Entwicklung des >me8nder< Trockenverlegesystems für Sanierungsanwendungen

2015

Markteinführung von hpg inverse®, einem innovativen PE-RT-Rohr mit umgekehrtem Schichtaufbau

2023

Akquisition der hpg Plastics GmbH durch die Huliot Group

Quality comes

first for us

hpg Plastics is more than just an extrusion company – we are a development partner and competence center for the world’s largest plastics manufacturers, helping them advance new pipe materials with our expertise in processing and application technology. We continuously push boundaries to unlock new market potential and create fresh opportunities for our customers. Through our in-house R&D and laboratory, we offer tailored solutions, technical calculations, sample pipes, and pilot installations. The exceptional performance of PE-RT has led to its full standardization both in Germany (DIN 16833) and internationally (ISO 24033, ISO 22391, ISO 21003), making it the new standard in building projects. Safety and trust are the foundation of our partnerships. That’s why our products, processes, and quality management are regularly monitored by independent institutes.

With hpg Plastics, you get peace of mind, backed by a 10-year guarantee for damage compensation and a 40-year guarantee for pipe replacement.

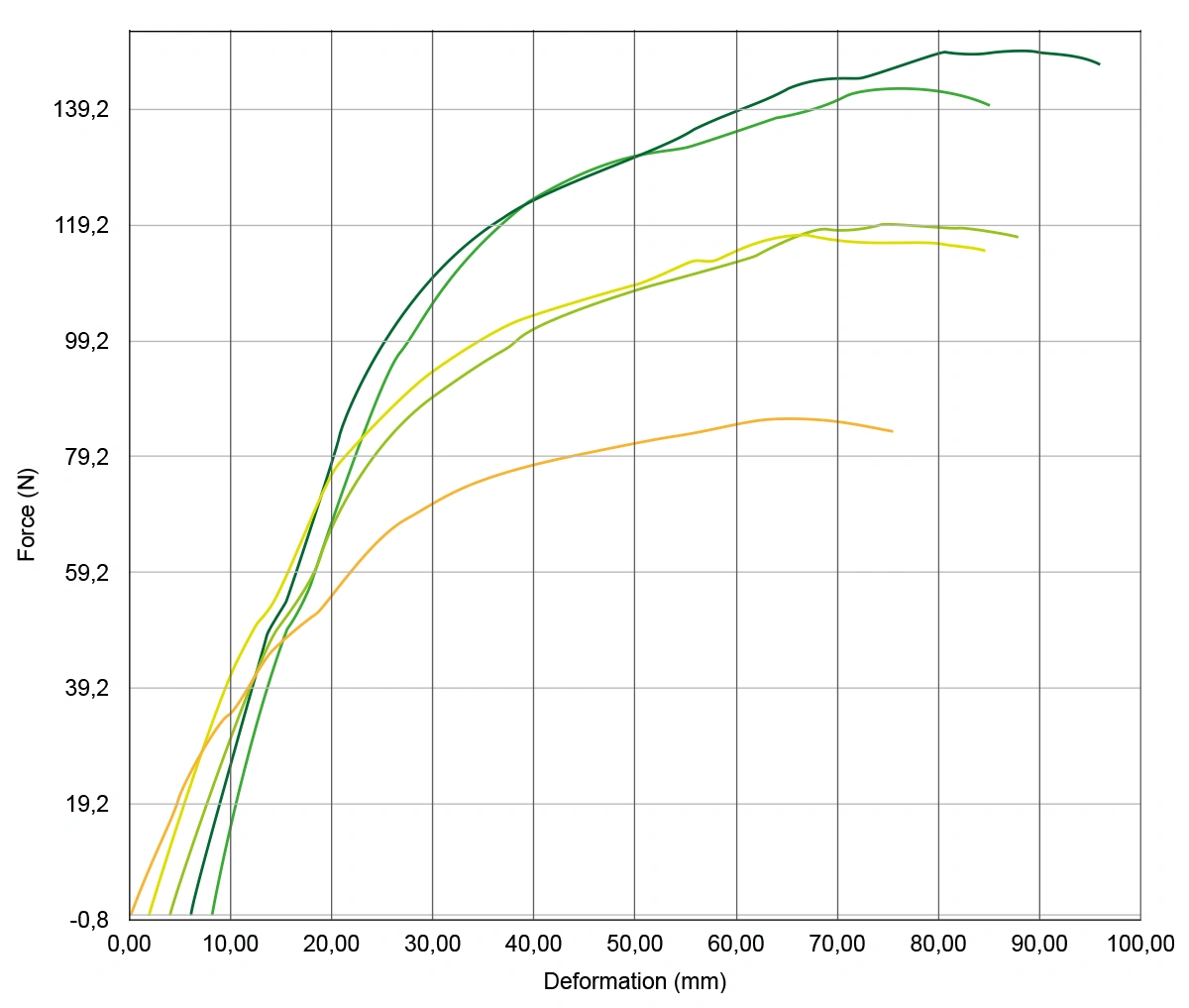

Flexibility difference of our PE-RT pipe types for underfloor heating in comparison with PEXc pipes.

The chart shows the amount of force needed in order to produce the same deformation to 5-layer pipes of same dimension but made of a different material.

Flexibility is our strength

Our customers’ success is our success. That is why we aim to turn individual requirements into perfect systems and products with enormous innovative capacity. You profit from the fact that we, as a well-established organisation with a long tradition, are consistently looking towards the future and the ever-evolving changes on the market.

In addition, we provide support through personal commitment at all levels of the company – from management, research and development to production and logistics.

Your Success is our goal

For over 40 years, our team has been working every day to develop innovative products of outstanding quality. The basis for the trust our customers place in us are our many years of expertise and the passion for our products. This enables us to offer reliable and customized solutions for a wide range of applications with maximum flexibility.

As a company with a long and rich history, we know that team-work is essential for the durability, quality and reliability of our products. Our sense of responsibility is reflected not only in our quality management and international certifications, but also in our awareness of sustainability and environmental protection.

Innovation through research and development

In keeping with our slogan “passion for pipes since 1984”, we create solutions that are among the most innovative on the market. For many years, we have been working closely with various plastics manufacturers in particular with the market leader DOW, giving us a clear innovative edge. Thanks to our expertise in materials and production, we carry out processing tests and investigations for these manufacturers and therefore have a deep insight into the latest materials. The best proof of the successful partnership between DOW and hpg Plastics is the fact that the PE-RT raw materials that we have developed together, are now standardized and used internationally. With its high pressure- and temperature-resistance and flexibility, this material has set new standards for the pipe industry. Customer orientation is the driving force behind the continuous improvement and expansion of our processes and products.

Values you can rely on

Flexibility

Innovation

Quality

Responsibility

Trust

Community

We value our resources

At hpg Plastics, we take our responsibility towards the environment and its resources very seriously and are constantly working to optimize our production, processes and products with regard to sustainability. Our commitment is supported by the “Going Green Program” by Huliot Group, our parent company, which consistently develops sustainable measures in all business areas.

In our production, we continuously strive to implement sustainable processes, such as: using silos to store our raw materials, maximum pallet utilization, closed-loop water cooling systems on our machines. We have already successfully reduced our waste and general CO2 emissions and saved valuable resources.

We value our resources

At hpg Plastics, we take our responsibility towards the environment and its resources very seriously and are constantly working to optimize our production, processes and products with regard to sustainability. Our commitment is supported by the “Going Green Program” by Huliot Group, our parent company, which consistently develops sustainable measures in all business areas.

In our production, we continuously strive to implement sustainable processes, such as: using silos to store our raw materials, maximum pallet utilization, closed-loop water cooling systems on our machines. We have already successfully reduced our waste and general CO2 emissions and saved valuable resources.

The Huliot Going Green Program

In the past decade, Huliot Group has transformed into a green company, with the implementation of a rigorous Huliot Going Green program which focuses efforts on protecting the environment throughout our entire supply chain. Designed to minimize our carbon footprint across the group while creating economic value, the program has led us to transition to a more effective and less wasteful production strategy, and opened us up to new opportunities as resellers of residual materials.

PE-RT: the plastic of today and tomorrow

hpg Plastics not only invented PE-RT, we still produce products exclusively from PE-RT – and we are proud of it. Our pipes are fully recyclable. That means, that at the end of their service life, our products can be processed at a recycling facility in order to be re-used instead of landfilling and burning.

Further environmental benefits of PE-RT

PE-RT and its production are characterized by a number of positive properties that support the conservation of the environment compared to other plastic materials:

- PE-RT has a very long service life and is therefore not only cost-effective but also resource-saving.

- No toxic chemicals are used or emitted during the processing or handling of PE-RT products. This makes PE-RT a particularly safe material – for production staff, installers and the people who live with it.

- The production of our PE-RT products generally requires less energy than conventional heating pipe material.

- PE-RT is 100% recyclable.

hpg Plastics GmbH

Anna-Schlinkheider-Str. 3

40878 Ratingen

Germany

fon. +49 (0) 2102 7007 – 800

fax. +49 (0) 2102 7007 – 888